What flex connectors do: Flex connectors provide installation and operation flexibility within a fuel site’s piping systems.

How flex connectors work: Flex connectors feature a corrugated metal hose that is enclosed in a durable stainless steel wire braid. The connector’s strong-yet-flexible design enables the tube to bend. This feature allows piping to be connected to system components — such as sumps and shear valves — that are located in confined spaces. Machined of durable materials, flex connectors are engineered to be corrosion-resistant and to withstand high pressures. Flex connectors with quick clamp fittings install quickly and easily. Stainless steel styles are compatible with a wide range of current fuels and are likely to be compatible with future fuels and blends.

Source solutions: Source is proud to offer flex connectors from Hose Master, FLEX-ING™ and OmegaFlex®. Call (800) 572-5578 to order a flex connector today.

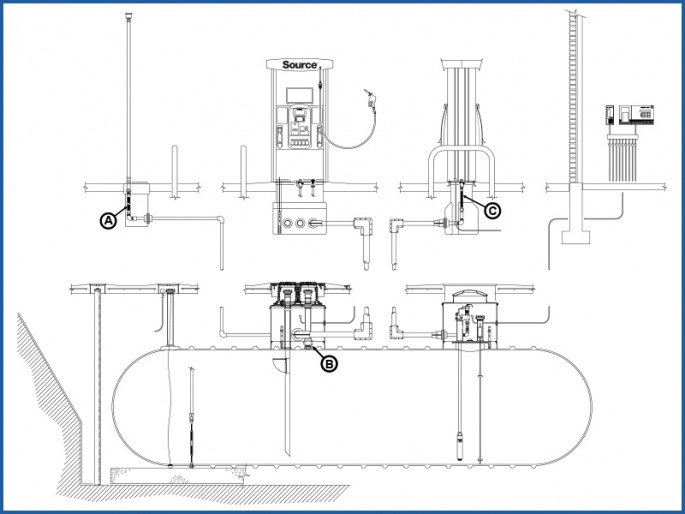

IN THE DIAGRAM:

- 2″ x 18″ FLEX CONNECTOR, M x F

- 3″ x 12″ FLEX CONNECTOR, M x M

- 1.5″ x 18″ FLEX CONNECTOR, M x F